Last week I was able to work with my friends Christine and Jon with their 3D printer (the FlashForge, a printer very similar to the MakerBot) in order to do some more specific line testing!

The problem I ran into testing on the Cube was that I wasn't able to print a single strand of filament on the build pad. Christine and Jon graciously let me use their 3D printer for a night of experimenting. They have a studio in a new co-working space in the Central West End, TechArtista.

The point of doing these line prints is to test the accuracy of the nozzle on printers that use the extrusion method.

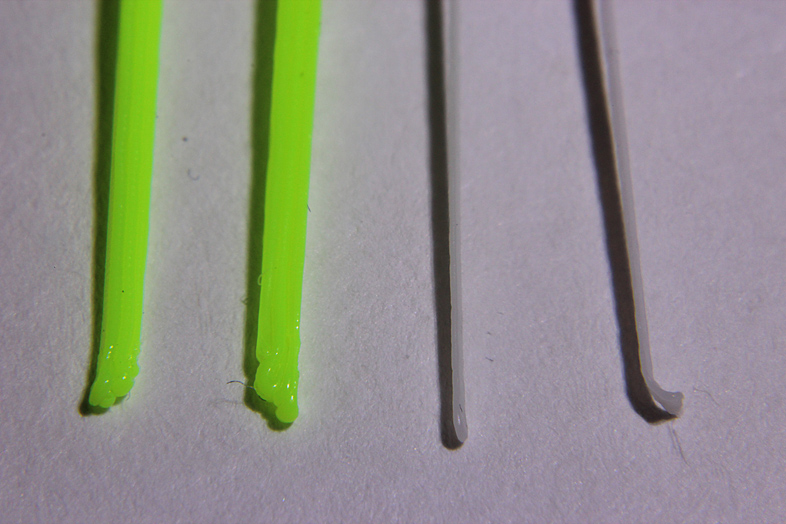

VS

The FlashForge has its own set backs. As you can see, where the blue tape touches on the build pad there were some issues with adhesion. Even so, Their printer did what my Cube could not: print a single strand of filament.

Since this experiment I have been comparing the results from the FlashForge to the results of the Cube. The Cube prints four layers of filament because of something in the G-code which states that a build must have two "bottom" layers and two "top" layers to begin and finish the object. The FlashForge printed a nice thin layer of filament that was very close to the file size. Both lines have inconsistent ends.